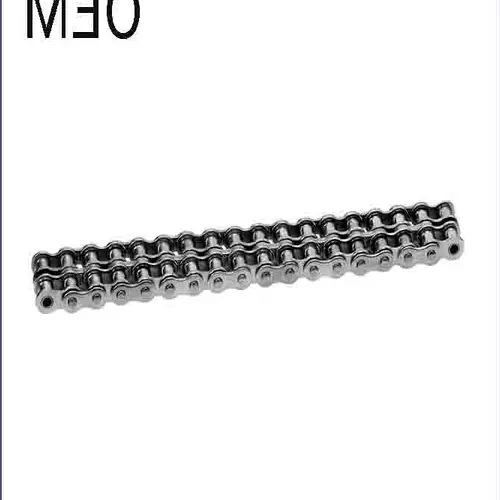

China OEM Alloy Steel Conveyor Chain High Strength Agricultural Machinery Baling Machine Chains air compressor for car

The China OEM Alloy Steel Conveyor Chain is a high-strength chain designed for use in agricultural machinery and baling machines. Made from alloy steel, this chain offers durability and reliability in demanding applications. With its high tensile strength, it can withstand heavy loads and provide efficient performance. The chain is specifically designed for use in air compressors for cars, ensuring smooth and reliable operation.

Ten Core Technologies

| 1 | Chain strength preload technology | 2 | Pin CRV treatment technology |

| 3 | Plate smoothly punching technology | 4 | Bush oil hole technology |

| 5 | Vacuum Oiled Technology | 6 | Precision Punching Technology |

| 7 | Low frequency fatigue test technology for large size chain | 8 | Chain length comparison technology |

| 9 | Variation of silence design technology | 10 | Chain dynamic testing technology |

Certifications

Our China OEM Alloy Steel Conveyor Chain has been approved by various global quality system certifications, including those from France, Norway, and Germany. We prioritize product quality and have established a sophisticated production management process and quality control system. With advanced production, processing, and testing equipment, we have leading full-process quality control capabilities to ensure the delivery of high-quality products to our customers.

Product Advantages

- High tensile strength and durability

- Designed for use in agricultural machinery and baling machines

- Suitable for air compressors in cars

- Smooth and reliable operation

- Manufactured with advanced technologies

- Customizable and adaptable to various applications

FAQs

1. Is the China OEM Alloy Steel Conveyor Chain suitable for heavy-duty applications?

Yes, the chain is designed to withstand heavy loads and provide efficient performance in demanding applications.

2. Can the chain be used in air compressors for cars?

Absolutely, the chain is specifically designed for use in air compressors for cars, ensuring smooth and reliable operation.

3. What certifications does the China OEM Alloy Steel Conveyor Chain have?

The chain has been approved by various global quality system certifications, including those from France, Norway, and Germany.

4. Can the China OEM Alloy Steel Conveyor Chain be customized?

Yes, we offer customization services to meet the specific needs of our customers. Drawings and samples are welcome for customization.

5. What are the advantages of the China OEM Alloy Steel Conveyor Chain?

- High tensile strength for heavy-duty applications

- Durable and reliable performance

- Suitable for air compressors in cars

- Manufactured with advanced technologies

- Customizable to various applications

EVER-POWER GROUP, our parent company, offers a wide range of industrial products, including agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. We take pride in providing high-quality products, competitive prices, and excellent customer service. We welcome customers to customize their products according to their specific requirements, and our professional team is ready to assist in the design process.

All the content of this page is from the Internet. The content is only for reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks mentioned in the content. Our products are only suitable for after-sales replacement parts and not original spare parts. Our replacement parts can be perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory to purchase. If you want to buy original spare parts, please contact the original supplier.

Performance Characteristics of Conveyor Chain

Conveyor chains have several performance characteristics that make them highly suitable for various applications:

1. High Load Capacity: Conveyor chains are designed to handle heavy loads, making them ideal for industries with demanding material handling requirements.

2. High Speed Capability: These chains can operate at high speeds, ensuring efficient and continuous movement of materials.

3. Low Maintenance: Conveyor chains are known for their durability and require minimal maintenance, reducing downtime and increasing productivity.

4. Flexibility: These chains can be customized to fit different conveyor systems and layouts, allowing for versatile usage in various industries.

5. Noise Reduction: Conveyor chains are designed to minimize noise during operation, creating a more comfortable working environment.

Types and Characteristics of Conveyor Chain

There are various types of conveyor chains available, each with its own unique characteristics:

1. Roller Chains: Roller chains consist of interconnected rollers that allow for smooth movement and are commonly used in applications that require precision and reliability.

2. Silent Chains: Silent chains are designed to reduce noise during operation and are often used in industries where noise reduction is a priority, such as the automotive industry.

3. Leaf Chains: Leaf chains are known for their high strength and are frequently used in heavy-duty applications, such as lifting and hoisting equipment.

4. Paddle Chains: Paddle chains feature paddles or attachments that are used to move bulk materials, making them suitable for industries that deal with bulk handling.

5. Hollow Pin Chains: Hollow pin chains have hollow pins that allow for the attachment of various accessories, making them highly adaptable and versatile.

Advantages of Conveyor Chain Made of Different Materials

The material used in the construction of conveyor chains plays a crucial role in their performance and durability. Here are the advantages of conveyor chains made from different materials:

1. Stainless Steel Chains: Stainless steel chains offer excellent corrosion resistance, making them suitable for applications in environments with high humidity or exposure to chemicals.

2. Carbon Steel Chains: Carbon steel chains are highly durable and cost-effective, making them a popular choice for general-purpose applications.

3. Plastic Chains: Plastic chains are lightweight, corrosion-resistant, and low-noise, making them ideal for industries that require clean and quiet operation.

4. Alloy Steel Chains: Alloy steel chains are known for their high strength and are often used in heavy-duty applications where robustness is essential.

5. Nickel-Plated Chains: Nickel-plated chains offer enhanced corrosion resistance and improved aesthetics, making them suitable for applications where appearance matters.

Application of Conveyor Chain in Various Industries

The versatility of conveyor chains makes them indispensable in numerous industries. Here are some examples of their applications:

1. Automotive Industry: Conveyor chains are used in assembly lines and manufacturing processes to transport car components, ensuring efficient production.

2. Pharmaceutical Industry: Conveyor chains are utilized in pharmaceutical manufacturing to move drugs and medications through different stages of production.

3. Agricultural Sector: Conveyor chains are employed in agricultural machinery to handle and transport crops, improving efficiency in harvesting and processing.

4. Textile Industry: Conveyor chains are crucial in textile manufacturing, facilitating the movement of fabrics and garments during production.

5. Energy Sector: Conveyor chains are used in power plants and renewable energy facilities to transport fuel, biomass, and other materials for energy production.

Future Development Trends and Opportunities of Conveyor Chain Products

The conveyor chain industry is continuously evolving, and several future development trends and opportunities can be observed:

1. Automation and Robotics Integration: The integration of conveyor chains with automation and robotics technologies will enhance efficiency and productivity in various industries.

2. Environmentally Friendly Solutions: The development of conveyor chains that reduce energy consumption and minimize environmental impact will gain prominence.

3. Advanced Material Technology: The use of innovative materials with enhanced durability and performance characteristics will improve the quality and longevity of conveyor chains.

4. IoT Integration: The integration of Internet of Things (IoT) technologies will enable real-time monitoring and predictive maintenance of conveyor chains, reducing downtime.

5. Global Market Expansion: The increasing demand for conveyor chains in emerging economies presents significant growth opportunities for manufacturers and suppliers.

How to Choose a Suitable Conveyor Chain

Choosing the right conveyor chain for your specific needs requires careful consideration. Here are some aspects to analyze:

1. Determine Application Requirements: Understand the specific requirements of your application, such as load capacity, speed, and environmental conditions.

2. Identify the Type of Chain: Select the appropriate chain type based on the nature of your application, considering factors like precision, noise reduction, or heavy-duty requirements.

3. Select the Chain Material: Choose a chain material that suits the environmental conditions and operational demands of your application, balancing factors like corrosion resistance and strength.

4. Consider the Chain Dimensions: Ensure that the chain dimensions, including pitch, width, and length, align with the requirements of your conveyor system.

5. Check Compatibility with Sprockets: Verify that the selected chain is compatible with the sprocket size, tooth profile, and tooth count of your conveyor system.

By carefully analyzing these aspects, you can make an informed decision and select a conveyor chain that meets your specific requirements.

In conclusion, conveyor chains offer excellent performance characteristics, and their various types and materials provide versatility for different applications. Their widespread use in industries like automotive, pharmaceutical, agriculture, textile, and energy highlights their value and importance. The future of conveyor chain products holds promising trends and opportunities, including advancements in automation, environmental solutions, material technology, IoT integration, and global market expansion. By following a systematic approach to choosing a suitable conveyor chain, businesses can optimize their material handling processes and enhance overall efficiency.

Author: Dream